Cross razor wires are generally equipped with short or medium blades. Two adjacent razor wire coils are crossed and clamped together with clips made of stainless steel or galvanized steel sheets to form cross razor wires. Stretching the cross razor wire roll, it expands like a concertina, therefore, it is also called as concertina cross razor wire.

After installation, blades are orderly arranged at regular intervals and the spacing between loops is smaller than that of single coil razor wires, thereby offering better security protection.

Cross razor wires are widely used in rural areas for crop protection, apartments, schools, factories, parking lots, warehouses and other places requiring a medium level security protection.

Cross razor wires are widely used in rural areas for crop protection, apartments, schools, factories, parking lots, warehouses and other places requiring a medium level security protection.

For school perimeter protection

For expressway protection

For factory property protection

For rural area crop protection

Inner waterproof paper + outer woven bag, carton or customized upon request.

Waterproof paper + woven bag package

Carton package

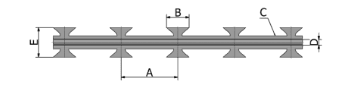

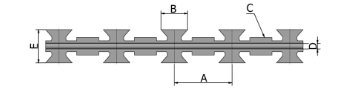

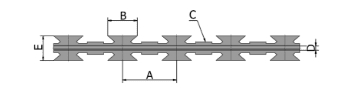

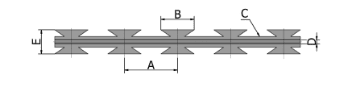

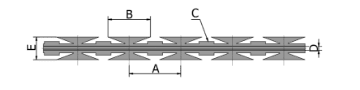

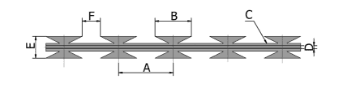

| Table 1: Specification of Cross Razor Wires | ||||||

| Reference Number | Blade Type | Barb Thickness C (mm) | Barb Length B (mm) | Barb Width E (mm) | Barb Spacing A (mm) | Core Wire Diameter D (mm) |

| BTO-10 |  |

0.5±0.05 | 10±1 | 13±1 | 25±1 | 2.5±0.1 |

| BTO-12 |  |

0.5±0.05 | 12±1 | 15±1 | 26±1 | 2.5±0.1 |

| BTO-18 |  |

0.5±0.05 | 18±1 | 15±1 | 33±1 | 2.5±0.1 |

| BTO-22 |  |

0.5±0.05 | 22±1 | 16±1 | 35±1 | 2.5±0.1 |

| BTO-28 |  |

0.5±0.05 | 28±1 | 15±1 | 45±1 | 2.5±0.1 |

| BTO-30 |  |

0.5±0.05 | 30±1 | 18±1 | 45±1 | 2.5±0.1 |

|

||||||

| Table 2: Specification of Cross Razor Wire Rolls | |||||

| Outer Diameter (mm) | Coil Loops (mm) | Clips | Loop Spacing (mm) | Extended Length (m) | Blade Type |

| 450 | 31 | 3 | 300 | 4.5 | BTO-10, BTO-12, BTO-18, BTO-22, BTO-28, BTO-30 |

| 600 | 31 | 3 | 400 | 6 | BTO-10, BTO-12, BTO-18, BTO-22, BTO-28, BTO-30 |

| 750 | 31 | 3 | 400 | 6 | BTO-10, BTO-12, BTO-18, BTO-22, BTO-28, BTO-30 |

| 900 | 31 | 3 | 400 | 6 | BTO-10, BTO-12, BTO-18, BTO-22, BTO-28, BTO-30 |