A complete set of quality control system is proven to be the best way to ensure product quality, meet customer demands and maintain a good reputation, thereby improving customer satisfaction and expanding company presence.

We implement strict quality control in all production links from raw material purchase, production management, product inspection, packaging and warehousing. We do everything we can to improve the quality of all production links to ensure all products received by our customers are qualified and can perfectly meet their demands.

A complete set of quality control system is proven to be the best way to ensure product quality, meet customer demands and maintain a good reputation, thereby improving customer satisfaction and expanding company presence.

All our workers must take part in pre-job training, get familiar with the operating procedures and precautions of their posts. We emphasis on every production detail and try our best to make every product as best as we can!

Production line parameter adjustment

Clean production environment

Strict warehouse partition

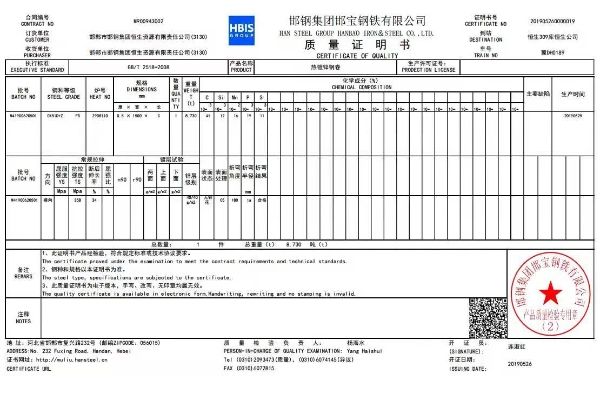

All our razor wires are tested to be qualified before leaving the factory to ensure all products received by our customers are qualified and meet their demands.

Blade thickness inspection

Core wire diameter inspection

Blade spacing inspection

Blade length inspection