Welded razor mesh, also known as razor mesh panel, is a versatile, high security fencing mesh made of cross-welded straight razor wires and is designed to protect you and your property without marring the appearance of the property.

Welded razor mesh often is available in both hot-dip galvanized and powder coated surfaces with the purpose of offering better corrosion resistance, enhanced aesthetic appearance and higher cost-effectiveness.

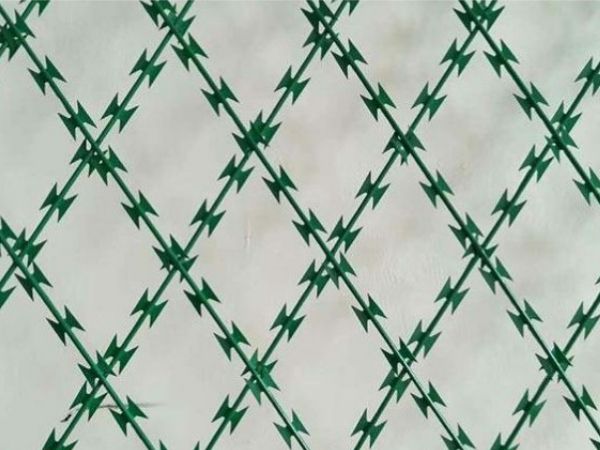

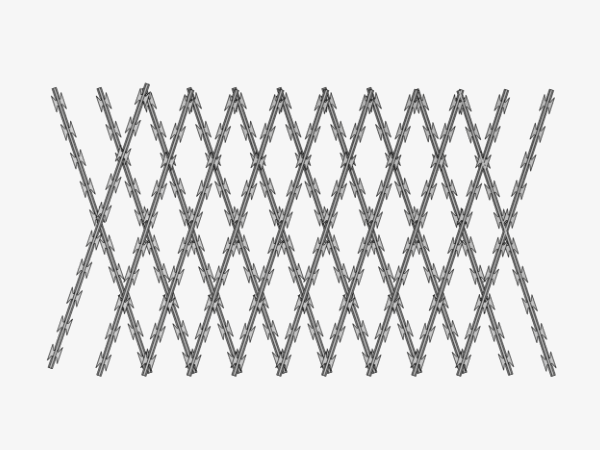

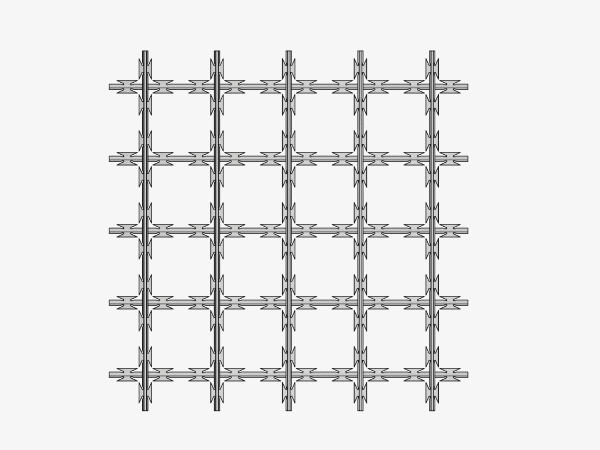

There are 3 types of mesh openings: diamond, square and rectangular. It can be used directly or welded with frames. Welded razor mesh is provided with sharp blades, you can neither hold nor climb over it, therefore, it is a perfect protective barrier for preventing illegal intruders and offering great security protection effect.

Welded razor mesh is widely used in the back fence lines of properties, around vacant land, on precast walls and around industrial areas to add more security.

Diamond welded razor mesh

Square welded razor mesh

Rectangular welded razor mesh

Welded razor mesh is widely used in prisons, detention houses, drug rehabilitation centers, military bases, residential communities, factories, private houses, government agencies, bank windows and doors, along highways or railways, etc.

For prison isolation

For highway protection

For private house security protection

For factory security protection

Available in both roll package and pallet package.

Roll package

Pallet package

| Table 1: Specification of Welded Razor Mesh | ||||||

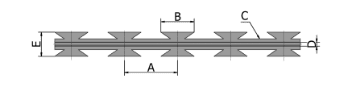

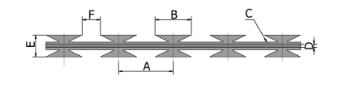

| Reference Number | Blade Type | Barb Thickness C (mm) | Barb Length B (mm) | Barb Width E (mm) | Barb Spacing A (mm) | Core Wire Diameter D (mm) |

| BTO-22 |  |

0.5±0.05 | 22±1 | 16±1 | 35±1 | 2.5±0.1 |

| BTO-30 |  |

0.5±0.05 | 30±1 | 18±1 | 45±1 | 2.5±0.1 |

| Table 2: Specification of Welded Razor Mesh Panels | |||

| Height (m) | Length (m) | Aperture Size (mm) | Blade Type |

| 1.2 | 3–6 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 1.8 | 3–6 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 2.1 | 3–6 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 2.4 | 3–6 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 3.0 | 3–6 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

|

|||

| Table 3: Specification of Welded Razor Mesh Rolls | |||

| Height (m) | Length (m) | Aperture Size (mm) | Blade Type |

| 1.2 | 20 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 1.8 | 20 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 2.1 | 20 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 2.4 | 20 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

| 3.0 | 20 | 75 × 150, 150 × 300, 100 × 150, 100 × 100, 40 × 40, 50 × 50, 60 × 60, 70 × 70, 80 × 80, 90 × 90 | BTO-22, BTO-30 |

|

|||